-

- Centrífugas de bancada

- Centrífugas de piso

- Centrífugas refrigeradas

- Microcentrífugas

- Centrífugas multiúso

- Centrífugas de alta velocidade

- Ultracentrífugas

- Concentrator

- High-Speed and Ultracentrifugation Consumables

- Diversos

- Tubos

- Placas

- Gerenciamento de dispositivo

- Gerenciamento de amostras e informação

Regarding suitability of Eppendorf bioprocess equipment in GMP-regulated applications, please reach out to your Eppendorf sales representative.

Bioprocessing in Vaccine Development

Read more

Read less

Our bioprocess solutions for vaccine development

Read more

Read less

Scalable bioprocess systems

Read more

Read less

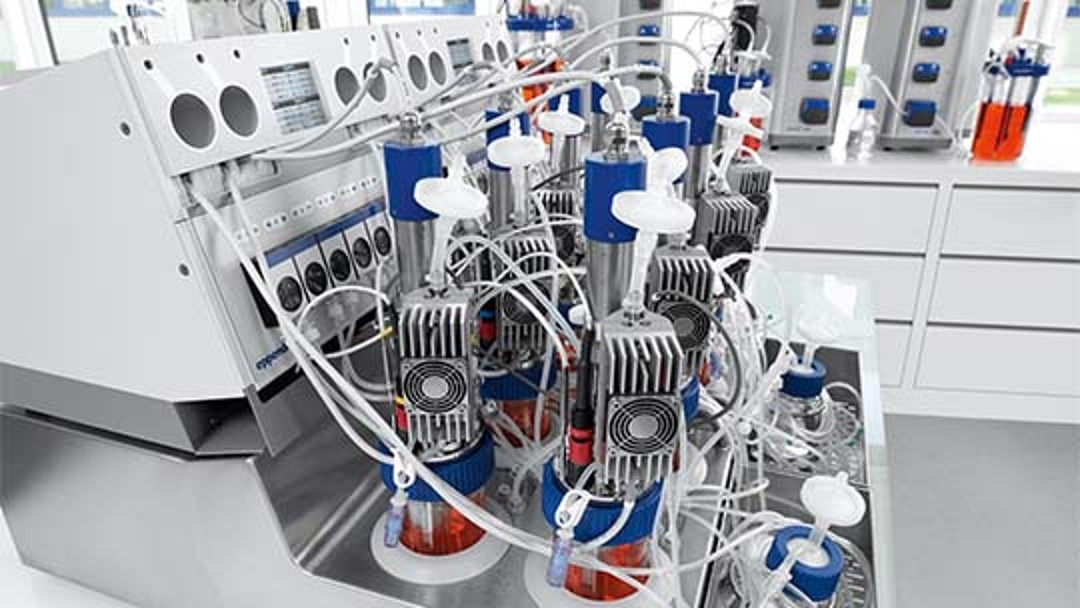

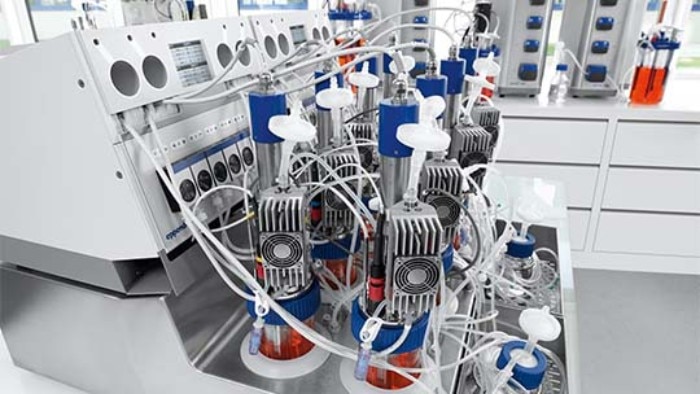

The Eppendorf range of bioreactor systems:

- Small-scale: DASbox® Mini Bioreactor System and DASGIP® Parallel Bioreactor Systems

- Bench-scale:SciVario® twin, BioFlo® 120, BioFlo® 320

- Pilot/production-scale: BioFlo® 720, BioFlo® 510/CelliGen 510, BioFlo® 610, BioFlo® Pro

Single-use bioreactors

The use of single-use bioreactors increases turn-around, eliminates the need for bioreactor cleaning, and decreases the risk of cross-contamination. Eppendorf offers a large portfolio of single-use bioreactors for use in vaccine development. Regardless of the cells you employ to make vaccines, there are single-use bioreactors created specifically for your needs, for example:

- Microbial cells: BioBLU® f Single-Use Bioreactors (65 mL to 3.75 L)

- Cell Culture: BioBLU® c and p Single-Use Bioreactors (100 mL to 40 L)

- Cell Culture: BioFlo® 720 control station compatible with Thermo Scientific® HyPerforma® Single-Use Bioreactors (50 L to 500 L)

Cell culture in perfusion

Eppendorf offers solutions for upstream bioprocessing in perfusion:

- Bioreactor systems connectable to filtration devices for cell retention

- Bioreactor systems connectable to Cell-Lift impeller and decanter column

- Packed-bed bioreactors filled with Fibra-Cel® Disks

Find more information about these cell retention technologies and how to use them with the Eppendorf bioreactor systems

Read more

Read less

Cultivation of adherent cells

Some cell types used in vaccine development, including Vero cells, are anchorage-dependent cells requiring a growth matrix to adhere to in order to be cultivated in stirred-tank bioreactors. There are two main approaches to ensure these cell types are retained correctly:

- Microcarriers: beads in suspension to which adherent cells can attach and grow in bioreactors

- Packed-bed bioreactors: bioreactors with a fixed bed of Fibra-Cel® Disks on which the cells are immobilized

Find out more about the cultivation of anchorage-dependent cells in Eppendorf bioreactors!

The value of bioreactors in vaccine development

Read more

Read less

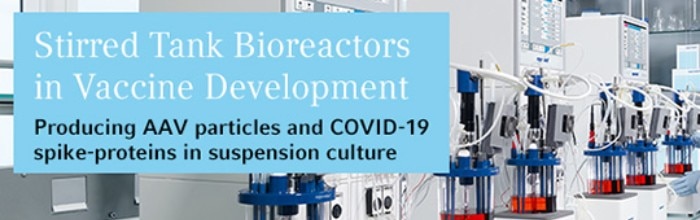

Webinar: Stirred tank bioreactors in vaccine development

The use of cell culture in bioreactors offers a standardized, scalable, and cost-effective procedure for developing vaccines. Learn, how suspension cells were efficiently cultivated in bioreactors to produce AAV particles and COVID-19 spike-proteins in suspension culture.

Process development

Read more

Read less

Read more

Read less

Bioprocess scale-up

Read more

Read less

Read more

Read less

Process intensification

Read more

Read less

Read more

Read less

How our customers use our products

Read more

Read less

A selection of our customers

Read more about the different vaccine types

- Live attenuated vaccines that use a weakened (attenuated) version of the pathogen e.g., the measles, mumps, rubella (MMR) vaccine

- Inactivated vaccines that use an altered or killed version of the pathogen that cannot replicate e.g., rabies vaccine

- Subunit vaccines and toxoid vaccines that use protein, polysaccharide, or the pathogen capside.g., hepatitis B vaccine

- DNA and RNA vaccines that use DNA or RNA that codes for antigens from the pathogen, e.g., some COVID-19 vaccines

Read more

Read less

Read more

Read less

Read about the advantages of bioreactors for vaccine production

Read more

Read less

Read more

Read less

Read more

Read less

Discover more advantages of vaccine development using mammalian cells

Get to know more about approaches and trends in vaccine development production

Infographic: Vaccine development workflow

The vaccine development journey involves several stages, from selecting lead candidates to process development, and manufacturing. Gain a better understanding of the vaccine development workflow, and learn about the problems and potential solutions of each stage.

ebook: Challenges in upstream bioprocessing

Vaccine manufacturers are facing the challenge of developing new products to serve unmet needs and fulfill the demands in an economically viable way. Read expert views and case studies on some of the hot topics in vaccine bioprocess development.

ebook: Cultivation of adherent and suspension cells

Discover application examples for the cultivation of adherent and suspension cells for vaccine development.

Panel discussion: Trends in vaccine development

Check out this video of experts discussing trends in vaccine development including automation.